Conformal cooling par excellence

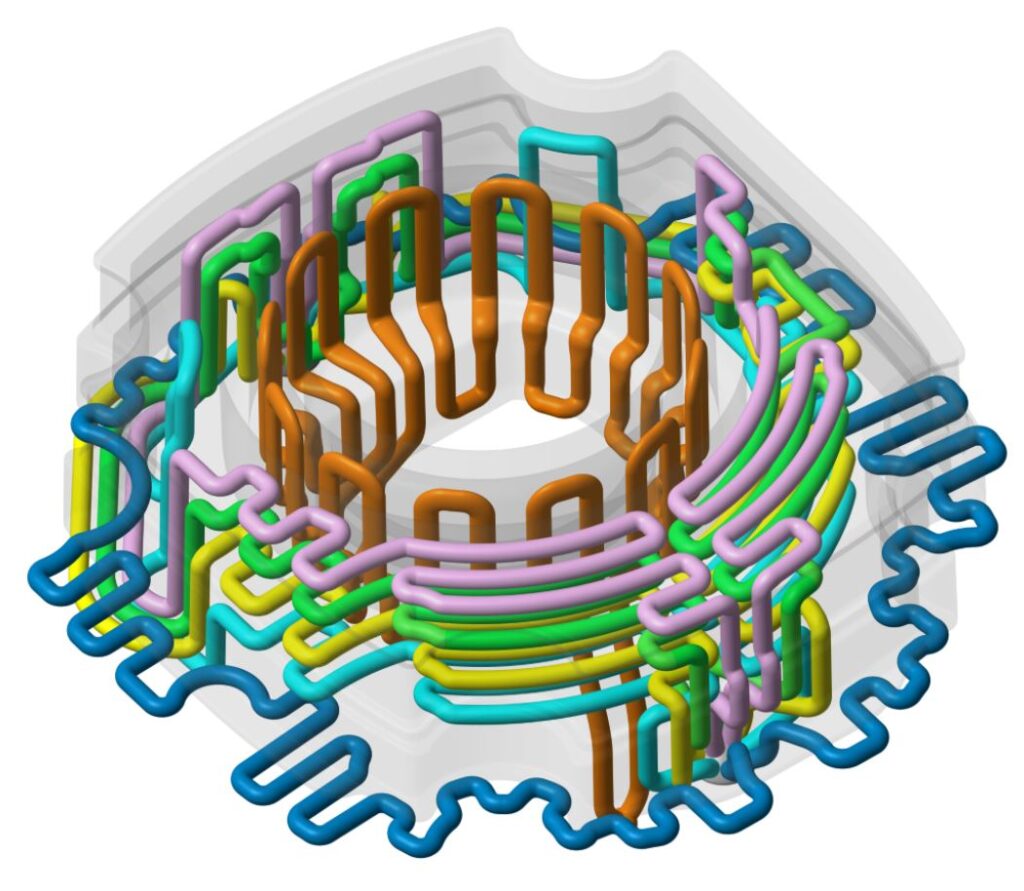

iQ-System conformal cooling

Within the hotset Group, iQtemp is the competence center for conformal cooling and temperature control of injection and die casting tools.

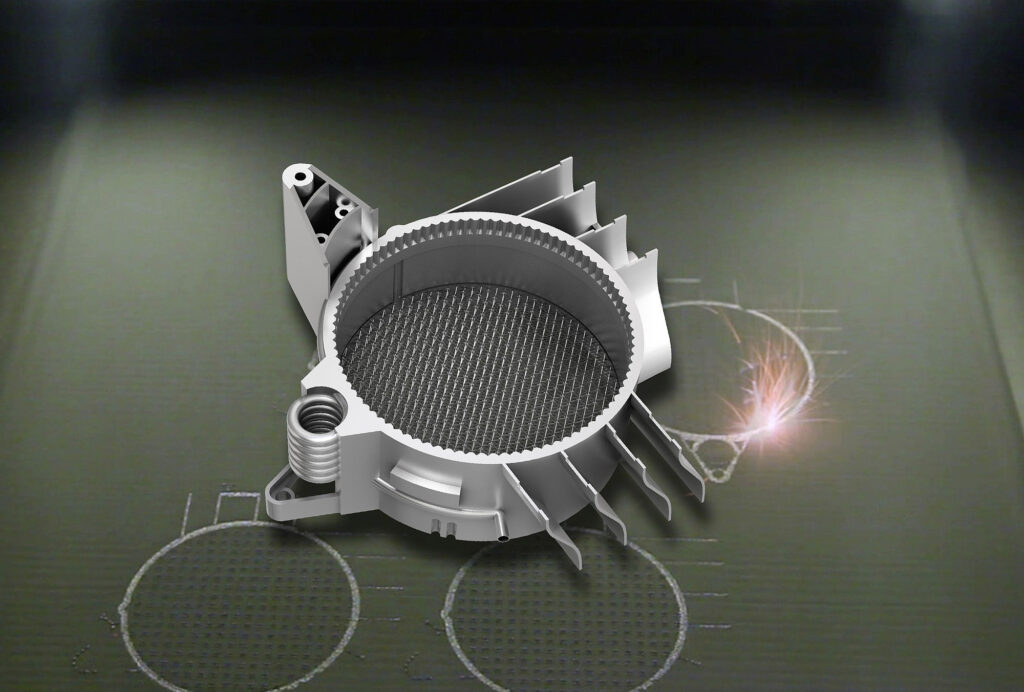

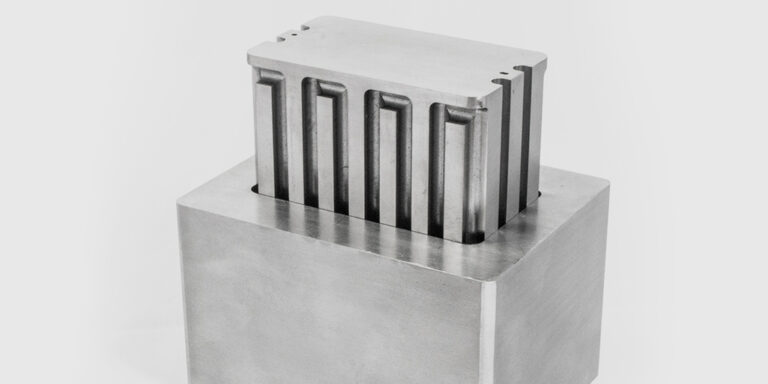

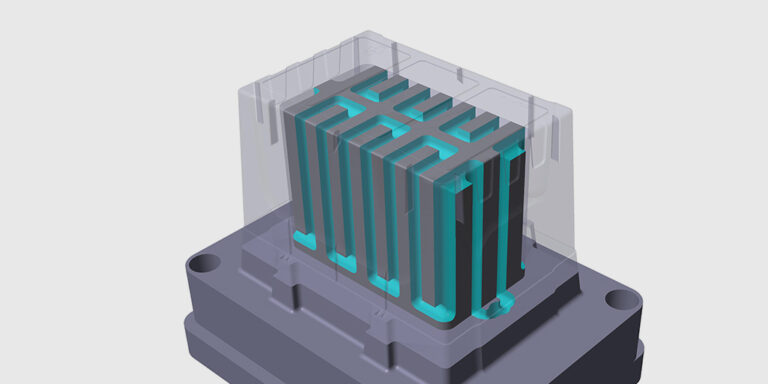

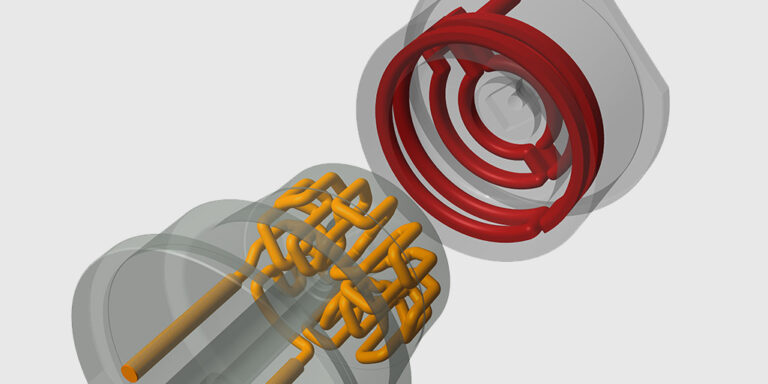

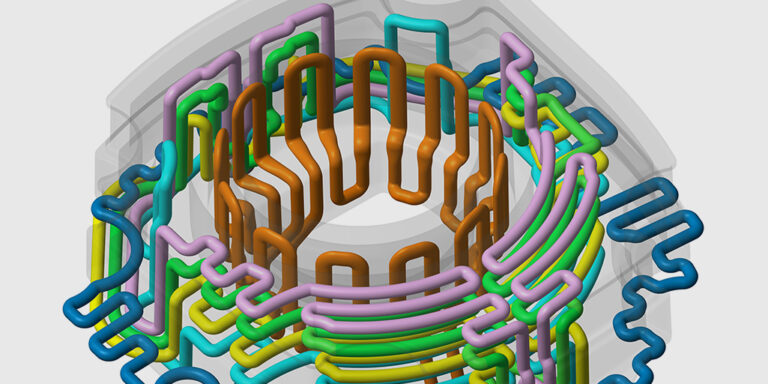

The components of these tools (mold cores, mold inserts, slides, manifolds) are manufactured using additive manufacturing, vacuum brazing and diffusion bonding.

Our team has many years of experience in the design and optimization of these innovative components.

This enables us to create an intelligent mix of technologies to realize sophisticated solutions and open up unexpected possibilities and advantages regarding performance, quality, energy and cost savings.

Our range of services

By maintaining close contacts with associations, research institutions, and other companies of the industry such as coaters and software companies, we are able to continuously expand our range of services. One single contact provides you access to almost all specialists on the market. The services can be requested individually or combined as needed.

At iQtemp, you have the opportunity to choose from the following portfolio of services:

iQtemp – the competence center for conformal cooling

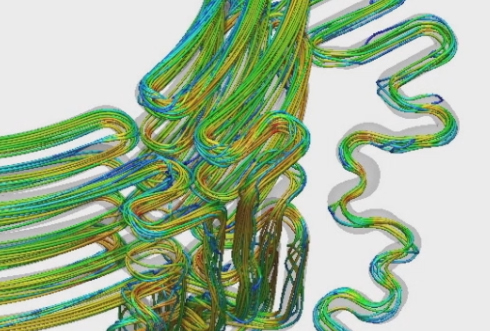

Mixing different technologies to achieve maximum performance in temperature control of injection molds and diecasting tools. The combination of vacuum brazing and laser generation creates unprecedented possibilities and benefits.

iQtemp allows customers to choose from the following range of services the ones that suit their specific needs. One single contact provides you access to the experts for all the technologies applied in conformal temperature control. With a unique range of services and outstanding flexibility, we can offer you a tailored solution for temperature control of your mold inserts.

iQtemp is a division of Hotset GmbH and the competence center for conformal cooling and temperature control of injection and die casting tools. In addition to the design of optimized temperature control and simulation, iQtemp offers implementation using various processes. These currently include additive manufacturing, vacuum brazing and electron beam welding. To complement the portfolio, customers can also request corrosion protection coating for the temperature control channels and a stainless steel line filter to protect the channels from contamination and blockages.

In close cooperation with other experts in near-contour temperature control, such as software manufacturers, iQtemp offers customers the unique benefit of receiving complete solutions for their tasks from a single point of contact. Our many years of expertise enable us to provide solution-oriented, cross-technology advice and tried-and-tested implementation.