Individual simulation is an essential tool to ensure economic efficiency.

Simulation

Your simulation package could include the following functions:

- Simulation of the existing tool and reproduction of your casting process. This requires a detailed data sheet on the casting process and the material used.

- Determination of the factors influencing the cycle time.

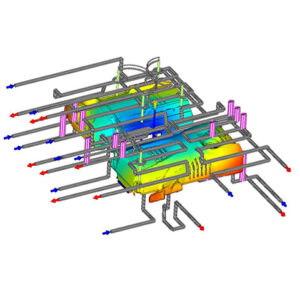

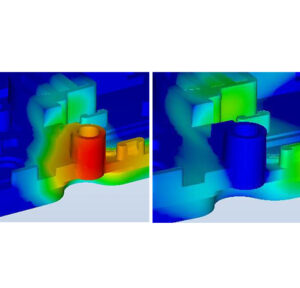

- Optimization of conventional tool temperature control in order to optimize the casting process.

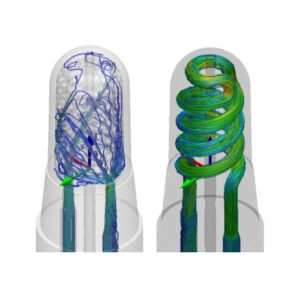

- Design of the conformal temperature control system.

- Comparative simulation of the optimized tool with parameter determination.

- Evaluation and presentation of results.

Advantages:

- Injection molding simulation

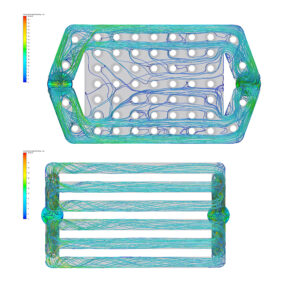

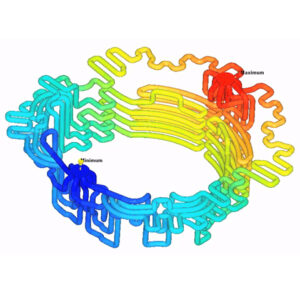

- Balancing of a complex temperature control system

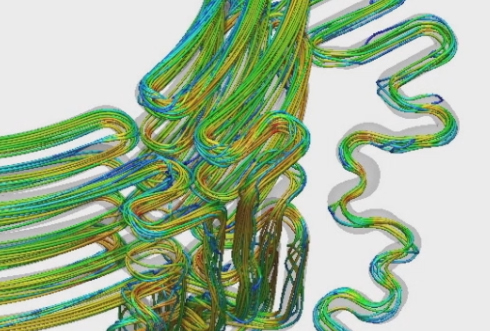

- CFD – flow rate, flow velocity

- CFD – heat dissipation

- FEM – structural analysis