See you in hall B2 — booth 2112.

Thanks to the recent acquisition of the technology service provider iQtemp, the German thermodynamics specialist hotset is now able to realize tempering systems that integrate dynamic heating and homogenous cooling in a way that is unique to date. These package solutions offer toolmakers in injection molding and die casting technology trendsetting perspectives for the production of intelligent tools for series production of low-stress molded parts with flawless surfaces. At the Fakuma trade fair, hotset will provide detailed information on the potential of the new combination systems in Hall B2.

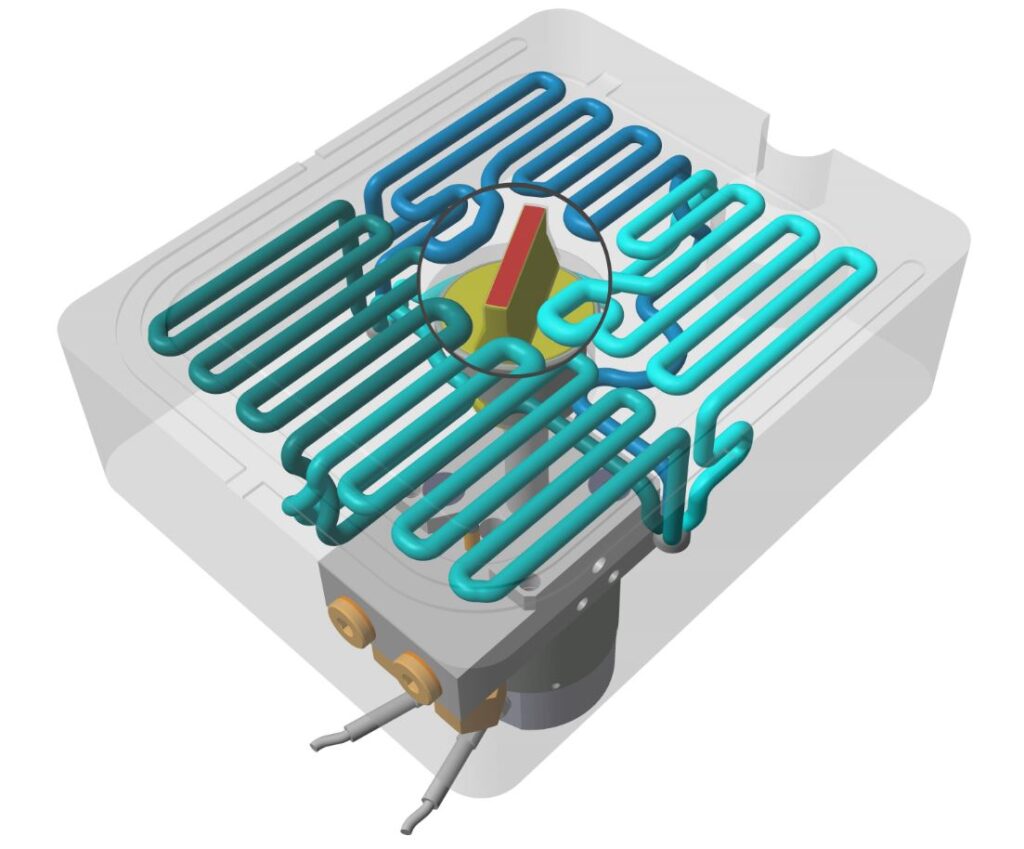

“The future belongs to intelligent temperature control”, says Sven Braatz, Sales Manager and proxy of hotset. Visitors to this year’s Fakuma can find out exactly what he means at booth 2112 in hall B2. Themed “controlled energy flow”, hotset development engineers will be providing information on the implementation of new temperature control systems that enable both the targeted heating of specific problem zones on the mold and homogeneous cooling of the cavities. These are integrated solutions consisting of several technical approaches. Primarily for toolmakers in injection molding and die casting, it will thus be possible to use intelligent temperature control systems that ensure series production of high-quality molded parts for use in automotive engineering, household appliances, medical engineering, electrical engineering and many other areas. Sven Braatz explains: Our new temperature control systems combine dynamic and partial heating of defined mold areas with heat dissipation parallel to the contour with balanced flow. They allow for extremely homogeneous, fast and surprisingly energy-saving temperature control. This results in plastic parts with low-stress structures, flawless surfaces, precisely contoured microstructures and immaculate thin-wall areas.”

DH-System meets cooling close to the contour

hotset’s new integrated temperature control systems enable moldmakers in injection molding and die casting to realize intelligent molds for the production of high-quality molded parts for use in automotive engineering, household appliances, medical engineering, electrical engineering and many other areas.

hotset created the technical possibilities for the realization of this new generation of intelligent temperature control systems on June 1, 2023 – just in the year of its 50th company anniversary – with the acquisition of the technology service provider iQtemp. This is because the resulting expansion of the range of competencies offers the German thermodynamics specialist and sensor manufacturer a unique opportunity for rapid integration of two of the currently most innovative process solutions in temperature control technology: the DH system developed by hotset and the iQ system. Both processes have already proven their performance in injection molding and die casting. They not only lead to molded parts of better quality, but also to process optimization and energy savings in production. “Using the new temperature control systems can reduce cooling times by up to 70 percent and in no way affects the cycle time — and thus productivity — of the injection molding and die casting lines”, emphasizes Carlo Hüsken, head of the iQ division.

Wide technological spectrum

Sven Braatz: “Our new temperature control systems combine dynamic and partial heating of defined mold areas with heat dissipation parallel to the contour with balanced flow.”

At Fakuma, the hotset specialists will be available to answer questions on all technical aspects of the two temperature control systems and their intelligent combination. Interested mold and die makers will learn, for example, that these package solutions are always optimally and individually tailored to each specific case and that a large number of different competencies merge for their implementation. While the specification and configuration of the DH system focuses on the disciplines of modern measurement, control and sensor technology, the technological spectrum for the implementation of the iQ system ranges from simulation and design technology, diffusion welding and vacuum brazing to additive manufacturing. “Special coating and corrosion protection techniques, which are used for reasons of surface and service life optimization, should not be forgotten at this point,”, says Carlo Hüsken.

Highlight for toolmaking

Carlo Hüsken: “Using the new temperature control systems reduces cooling times by up to 70 percent and in no way affects the cycle time of the injection molding and die casting lines.”

hotset will present a future-oriented technology highlight at this year’s Fakuma: realizing intelligent temperature control systems for injection molding and die casting technology that can process dynamic heating and homogeneous cooling precisely, even without impairing productivity and energy efficiency. It is a temperature control innovation for companies in the moldmaking and toolmaking industry that will strengthen their international competitive position in the long term. This is because the integrated complete solution consisting of DH and iQ systems is the technological answer to the growing quality and design requirements of customers in modern automotive engineering, medical engineering, installation technology and many areas of the consumer industry.